Filtermist introduced two brand new products, ‘Vortex’ and ‘F Monitor’ on its stand at this year’s EMO show which took place in Hannover last month. Both additions are accessories designed to enhance Filtermist oil mist extraction units and have been introduced to address specific issues as a result of market research.

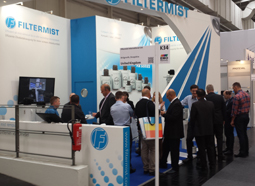

According to its organisers, EMO is the largest machine tool show in the world – more than 145,000 visitors from over 100 c ountries attended the 2013 show. Filtermist has attended since 1989 and footfall to this year’s stand was the best ever.

ountries attended the 2013 show. Filtermist has attended since 1989 and footfall to this year’s stand was the best ever.

Vortex and F Monitor were both extremely well received by visitors as Managing Director, James Stansfield, testifies, “We were really encouraged by both the volume of visitors to our stand and the level of enquiries we received. Our stand this year was one of our largest to date, and we’re already thinking about booking an ever bigger space for the 2015 show.

“EMO also provided an excellent opportunity for us to meet with a significant number of our global distributors, including new companies from Poland, to thank them for their continued hard work. More than 90% of our units are exported - this would not be possible without the support of our distributor network.”

Vortex

‘Vortex’ is a brand new pre-filter which has been specifically designed for use in high volume / low pressure coolant applications, such as multi-spindle machines. The volume of oil used in these applications means traditional oil filters can quickly become saturated, incurring additional replacement and disposal costs.

The Vortex sits underneath the Filtermist unit and is held securely in place with over centre lid clamps. The blades inside the unit force the saturated air to spiral, separating the large oil droplets from the air. The remaining oil mist then passes through the Filtermist unit as normal – oil is collected by both the Vortex and Filtermist unit and returned to the machine, and clean air is exhausted back into the workplace.

Operations Director, Randall Taft, says, “Filtermist is constantly looking at ways that it can improve its clients’ working environments and reduce their overheads. The Vortex addresses a problem that is an issue in a number of general engineering applications. Installing a Vortex will significantly reduce the number of replacement filters and associated disposal costs, as well as improving productivity and the air quality within the workshop.”

F Monitor

‘F Monitor’ is Filtermist’s new monitoring system which advises machine operators when the extraction unit needs servicing, or if any of the filters are blocked. Filtermist advises that its units should be serviced every 2000 hours they are in use - COSHH regulations in the UK also require all LEV systems to be tested every 14 months.

F Monitor measures the airflow inside the unit and also incorporates a timer to indicate when the unit is approaching 2000 hours of use. The system uses the traditional traffic-light coloured warning system, and when everything is working to optimum levels the monitor displays a green light. An amber warning light comes on to indicate that the operator needs to arrange a service and the monitor lights turn red if urgent inspection is required. Regular servicing ensures the Filtermist units achieve optimum performance 24/7 which is vital in high-volume applications where components are often made in three-shift patterns that require machine tools to be in constant use.

F Monitor can be retro-fitted to the complete Filtermist range and is sold as an optional accessory on all new units, contact your local distributor for more details.